Unscrew the Mystery: 29 Steps Inside a Light Bulb's Creation

The creation of a light bulb is a fascinating process that combines innovation, precision, and craftsmanship. Each step in this journey is meticulously designed to ensure the final product delivers reliable, efficient, and long-lasting light. Let’s delve into the 29 steps involved in bringing a light bulb from concept to reality.

1. Impact of Light Bulb Innovations on Various Industries

The advancements in light bulb technology have a significant impact across different sectors:

Residential Lighting

• Energy Savings: Modern LED bulbs use less energy and have a longer lifespan compared to traditional incandescent bulbs, leading to reduced electricity bills and lower environmental impact.

• Smart Homes: Integration of smart bulbs into home automation systems enhances convenience, security, and energy efficiency. Features like remote control, scheduling, and adaptive lighting improve the user experience.

Commercial and Industrial Lighting

• Cost Efficiency: In commercial settings, energy-efficient lighting solutions reduce operating costs and maintenance expenses. LEDs are particularly beneficial in environments that require long hours of operation, such as factories and warehouses.

• Enhanced Work Environment: Improved lighting quality can enhance productivity and safety in workplaces. Proper illumination reduces eye strain and accidents, contributing to a better working environment.

Healthcare

• Circadian Lighting: Hospitals and healthcare facilities are adopting circadian lighting systems that mimic natural light patterns to support the biological rhythms of patients and staff, promoting better sleep and overall well-being.

• Sterilization: UV-C lighting technology is used for sterilization purposes, effectively killing bacteria and viruses on surfaces, thus improving hygiene in medical settings.

Retail and Hospitality

• Customer Experience: Retail stores use dynamic lighting to highlight products and create an inviting atmosphere. Hospitality venues leverage smart lighting to enhance guest experiences, offering customizable lighting in rooms and public spaces.

• Sustainability: Energy-efficient lighting solutions help businesses meet sustainability goals, attracting environmentally conscious customers and reducing operational costs.

Agriculture

• Horticultural Lighting: LED grow lights are optimized for plant growth, providing specific wavelengths of light that enhance photosynthesis and improve crop yields. These lights are used in indoor farming, greenhouses, and vertical farming setups.

• Energy Efficiency: Energy-efficient grow lights reduce the cost of electricity in controlled-environment agriculture, making sustainable farming practices more feasible and profitable.

2. Consumer Trends and Preferences

Consumer preferences are shaping the future of light bulb manufacturing:

Eco-Friendly Products

• Sustainable Choices: Consumers are increasingly seeking eco-friendly and sustainable products. Light bulb manufacturers are responding by using recyclable materials, reducing hazardous substances, and creating energy-efficient products.

• Energy Labels: Clear labeling on energy consumption helps consumers make informed choices, favoring bulbs that offer long-term savings and minimal environmental impact.

Customization and Aesthetics

• Design and Aesthetics: The aesthetic appeal of light bulbs, including vintage-style filament LEDs and customizable smart bulbs, is becoming a significant factor in consumer decisions.

• Personalization: Smart bulbs that offer customizable lighting settings, such as color temperature and brightness, cater to individual preferences and enhance user experience.

Technological Integration

• Smart Home Compatibility: Consumers are looking for lighting solutions that seamlessly integrate with their existing smart home ecosystems, including compatibility with voice assistants like Amazon Alexa, Google Assistant, and Apple HomeKit.

• User-Friendly Apps: Intuitive and user-friendly mobile apps for controlling smart lighting are essential for consumer satisfaction, offering features like remote control, scheduling, and scene creation.

3. Raw Material Preparation

• Glass: High-quality sand, soda ash, and limestone are melted at high temperatures to form molten glass, which is then molded into the shape of the bulb.

• Filament: Tungsten wire, known for its high melting point and durability, is used for the filament. The wire is coiled and sometimes double-coiled to increase efficiency and longevity.

4. Bulb Formation

• Glass Blowing: The molten glass is blown into bulb-shaped molds to create the outer shell of the light bulb.

• Sealing: The neck of the glass bulb is sealed to prepare for the insertion of the filament and other components.

5. Filament Assembly

• Coiling: Tungsten wire is coiled into the desired shape, typically a double helix, which increases the filament’s strength and efficiency.

• Mounting: The coiled filament is mounted on support wires and connected to lead wires that will conduct electricity to the filament.

6. Gas Filling

• Inert Gas Injection: The bulb is filled with an inert gas, such as argon or nitrogen, to prevent the tungsten filament from oxidizing and to prolong the bulb’s life.

• Vacuuming: Some bulbs, particularly incandescent ones, have air evacuated from them to create a vacuum.

7. Base Attachment

• Base Sealing: The metal base, which includes the electrical contact points, is attached to the glass bulb. This is done using a cement that can withstand high temperatures and ensure a secure connection.

• Electrical Connection: The lead wires from the filament are connected to the base, ensuring proper electrical flow when the bulb is in use.

8. Testing and Quality Control

• Electrical Testing: Each bulb is tested to ensure it lights up and operates correctly. This involves checking for proper electrical resistance and functionality.

• Quality Control: Bulbs are inspected for defects in the glass, filament, and overall construction. Only those meeting strict standards are packaged for sale.

9. Packaging

• Protection: The bulbs are carefully packaged to prevent damage during transport. They are placed in protective sleeves or boxes and then packed into larger cartons for shipment.

CARTOON CHARACTER MUNFACTURING LIGHT BULB

10. Distribution

• Shipping: The finished bulbs are distributed to retailers, wholesalers, or directly to customers.

This process combines precision engineering with quality materials to produce reliable light bulbs used in various applications worldwide.

Specialized Light Bulbs

Some light bulbs undergo additional steps depending on their type and intended use:

LED Bulbs

• Semiconductor Production: LED bulbs use semiconductor materials such as gallium arsenide to create light through electroluminescence. The semiconductor materials are layered and processed to form the LED chip.

• Chip Encapsulation: The LED chip is mounted onto a heat sink and encapsulated in a plastic or epoxy resin to protect it and diffuse the light.

• Driver Circuit Integration: LEDs require driver circuits to regulate power. These circuits are integrated into the bulb’s base.

• Heat Management: LED bulbs include components to manage heat, such as heat sinks, to ensure longevity and efficiency.

Fluorescent Bulbs

• Phosphor Coating: The interior of the glass tube is coated with phosphor. When exposed to ultraviolet light, the phosphor emits visible light.

• Mercury Filling: A small amount of mercury is added to the tube. When electric current passes through, it vaporizes the mercury, producing ultraviolet light.

• Sealing and Electrode Attachment: Electrodes are attached at each end of the tube, and the tube is sealed.

• Gas Filling: The tube is filled with an inert gas, usually argon, which helps the electric current flow more easily.

11. Environmental and Safety Considerations

• Recycling: Many light bulbs, especially those containing hazardous materials like mercury, are subject to recycling regulations. Manufacturers often set up take-back programs to ensure proper disposal and recycling.

• Energy Efficiency: Modern light bulb manufacturing focuses on improving energy efficiency and reducing environmental impact. LED bulbs, for instance, use significantly less energy than traditional incandescent bulbs.

• Compliance: Manufacturers must comply with various international standards and regulations to ensure safety and performance, such as RoHS (Restriction of Hazardous Substances) and ENERGY STAR certifications.

12. Innovation and Development

• Research and Development: Continuous R&D efforts aim to improve bulb efficiency, longevity, and light quality. Innovations include smart bulbs with wireless control and customizable lighting systems.

• Advanced Materials: New materials are being explored to enhance performance. For instance, advancements in quantum dots for LEDs are improving color rendering and efficiency.

13. Future Trends in Light Bulb Manufacturing

The light bulb industry is continuously evolving with advancements in technology and changing consumer demands. Here are some future trends and innovations in light bulb manufacturing:

Smart Lighting

• Internet of Things (IoT): Smart bulbs that can be controlled via smartphones, voice assistants, and home automation systems are becoming more popular. These bulbs offer features like dimming, color changing, and scheduling.

• Energy Management: Smart bulbs can integrate with energy management systems to optimize power usage, contributing to energy conservation efforts.

Enhanced LED Technologies

• OLEDs (Organic Light Emitting Diodes): OLED technology offers flexible and thin lighting panels that can be used in various applications, including display screens and innovative lighting designs.

• Quantum Dots: Quantum dot technology is enhancing LED efficiency and color accuracy. This allows for brighter and more vibrant lighting options.

Sustainability and Eco-Friendly Practices

• Recycling and Circular Economy: The industry is increasingly focusing on recyclability and reducing environmental impact. Manufacturers are designing bulbs that are easier to recycle and contain fewer hazardous materials.

• Energy Efficiency Standards: Stricter energy efficiency standards and regulations are pushing manufacturers to develop bulbs that consume less power while providing the same or better quality of light.

Advanced Manufacturing Techniques

• 3D Printing: The use of 3D printing technology in manufacturing light bulbs can allow for rapid prototyping and customization, reducing production costs and time.

• Automation and Robotics: Automation in assembly lines improves efficiency and consistency in manufacturing, reducing human error and increasing production speed.

Improved Light Quality

• Color Rendering Index (CRI): There is a growing focus on improving the CRI of light bulbs, which measures the ability of a light source to reveal the colors of objects accurately.

• Human-Centric Lighting: Lighting designed to align with human circadian rhythms can improve well-being and productivity. This includes tunable white light that adjusts throughout the day.

Global Market Trends

• Emerging Markets: Growing urbanization and development in emerging markets are driving demand for advanced lighting solutions, offering new opportunities for manufacturers.

• Custom Lighting Solutions: Consumers and businesses are increasingly seeking customized lighting solutions that cater to specific needs and aesthetics.

14. Case Studies in Light Bulb Manufacturing

Examining specific examples can provide insights into how companies are implementing innovative practices and technologies in light bulb manufacturing:

Philips Lighting (Signify)

• Smart Lighting: Philips Hue is one of the leading brands in smart lighting. The system allows users to control lights via a mobile app or voice assistant, offering features like scheduling, color changing, and integration with other smart home devices.

• Sustainability Initiatives: Signify has committed to becoming carbon neutral and increasing the use of recycled materials in its products. They also promote the use of energy-efficient LEDs to reduce global energy consumption.

Cree Lighting

• LED Advancements: Cree has been at the forefront of LED innovation, focusing on increasing lumens per watt (efficiency) and improving the longevity of their bulbs. Their LED bulbs are known for high-quality light output and energy efficiency.

• R&D Investment: Cree invests heavily in research and development to push the boundaries of LED technology, including work on high-power LEDs and advanced materials like silicon carbide.

GE Lighting

• Connected Lighting: GE’s C by GE line of smart bulbs offers Bluetooth and Wi-Fi connectivity, enabling users to control lighting through apps and smart home systems. These bulbs emphasize ease of use and compatibility with existing smart home ecosystems.

• Quality and Innovation: GE Lighting has a long history of innovation, from pioneering the first commercial incandescent bulb to developing modern LED and smart lighting solutions. Their focus remains on delivering reliable and high-performance lighting products.

Four employees surround a manufacturing light bulb machine in an animated creative production line, with a yellow light bulb perched atop the machine

15. Challenges in Light Bulb Manufacturing

While the industry is advancing, it faces several challenges that manufacturers must navigate:

Cost and Pricing

• Production Costs: High-quality materials and advanced manufacturing techniques can increase production costs. Balancing cost with the need for innovation and quality is a constant challenge.

• Market Competition: The lighting market is highly competitive, with numerous players offering similar products. Manufacturers must differentiate themselves through innovation, quality, and pricing strategies.

Regulatory Compliance

• Environmental Regulations: Complying with environmental regulations, such as restrictions on hazardous substances (RoHS) and energy efficiency standards, requires continuous adaptation and investment.

• Safety Standards: Ensuring that products meet safety standards for various markets can be complex, particularly for international manufacturers.

Technological Advancements

• Rapid Technological Changes: Keeping up with rapid technological advancements in materials, electronics, and smart technology integration requires ongoing investment in research and development.

• Consumer Adoption: Encouraging consumers to adopt new technologies, such as smart lighting, involves addressing concerns about cost, ease of use, and compatibility with existing systems.

16. Future Outlook

The future of light bulb manufacturing is bright, with ongoing innovations and a focus on sustainability driving the industry forward. Key areas of growth include:

Advanced Materials

• Nano Materials: The use of nanotechnology in lighting can lead to more efficient and durable light bulbs, offering enhanced performance and new applications.

• Graphene: Incorporating graphene into light bulbs can improve conductivity and efficiency, opening up new possibilities for lighting design and functionality.

Integration with Renewable Energy

• Solar-Powered Lighting: Combining LED technology with solar power is becoming more viable, especially in off-grid areas and for outdoor lighting solutions, contributing to renewable energy adoption.

• Energy Storage: Advances in battery technology can enhance the effectiveness of solar-powered lighting systems, providing reliable and sustainable lighting solutions.

Global Expansion

• Emerging Markets: Expanding into emerging markets offers significant growth opportunities. Manufacturers can tap into the increasing demand for modern and energy-efficient lighting solutions in developing regions.

• Localization: Adapting products to meet local regulations, cultural preferences, and market conditions will be crucial for success in global markets.

17. Innovative Manufacturing Practices

In light bulb manufacturing, innovative practices are enhancing efficiency, quality, and sustainability. These practices include:

Lean Manufacturing

• Waste Reduction: Lean manufacturing focuses on minimizing waste in all forms, from raw materials to time and labor. This leads to cost savings and more efficient production processes.

• Continuous Improvement: Implementing a culture of continuous improvement (Kaizen) ensures that every aspect of the manufacturing process is regularly evaluated and optimized for better performance.

Automation and Robotics

• Precision and Consistency: Automation and robotics ensure high precision and consistency in manufacturing, reducing human error and increasing production speed.

• Advanced Assembly Lines: Automated assembly lines can handle complex tasks such as filament winding, glass molding, and component assembly with greater efficiency.

Additive Manufacturing (3D Printing)

• Prototyping: 3D printing allows for rapid prototyping, enabling manufacturers to quickly develop and test new designs without the need for costly molds and tooling.

• Customization: Additive manufacturing facilitates the creation of custom light bulb designs tailored to specific customer needs or niche applications.

Digital Twin Technology

• Simulations and Testing: Digital twins (virtual replicas of physical products) enable manufacturers to simulate and test various aspects of the light bulb’s performance before actual production, reducing the risk of defects and improving product quality.

• Predictive Maintenance: Monitoring the digital twin of manufacturing equipment can predict maintenance needs, reducing downtime and increasing the lifespan of machinery.

18. Advanced Quality Control Measures

Ensuring the quality and reliability of light bulbs is paramount. Advanced quality control measures include:

Automated Optical Inspection (AOI)

• Defect Detection: AOI systems use cameras and image processing software to inspect light bulbs for defects in the glass, filament, and other components, ensuring only high-quality products reach the market.

• Real-Time Monitoring: These systems provide real-time monitoring and feedback, allowing for immediate adjustments in the manufacturing process to address any issues.

Environmental Testing

• Temperature and Humidity: Light bulbs are subjected to various environmental conditions to ensure they can withstand temperature and humidity variations without performance degradation.

• Vibration and Shock: Testing for resistance to vibration and shock ensures that bulbs can handle transportation and installation without damage.

Electrical Testing

• Performance Metrics: Electrical testing verifies that bulbs meet performance metrics such as lumen output, power consumption, and color temperature.

• Safety Standards: Ensuring compliance with safety standards involves rigorous testing for electrical insulation, short-circuit protection, and heat dissipation.

19. Collaborations and Partnerships

Collaborations within the industry and with external partners drive innovation and growth:

Research Institutions and Universities

• Joint Research: Collaborations with academic institutions lead to breakthroughs in materials science, energy efficiency, and advanced manufacturing techniques.

• Talent Development: Partnerships with universities help in developing a skilled workforce familiar with the latest technologies and practices in light bulb manufacturing.

Industry Consortia

• Standardization: Participation in industry consortia helps establish and promote standards for quality, safety, and interoperability, benefiting both manufacturers and consumers.

• Shared Resources: Industry collaborations can lead to shared research facilities, reducing costs and accelerating innovation.

Technology Providers

• Integration of Advanced Technologies: Partnering with technology providers allows manufacturers to integrate cutting-edge technologies such as IoT, AI, and machine learning into their products and processes.

• Access to Expertise: These partnerships provide access to specialized expertise and support, enhancing the capabilities of the manufacturing company.

20. Consumer Education and Engagement

Educating consumers about lighting technology and engaging them in the product development process can drive market growth:

Educational Campaigns

• Energy Efficiency Awareness: Campaigns highlighting the benefits of energy-efficient lighting solutions can encourage consumers to switch to LED and smart lighting.

• Proper Disposal and Recycling: Educating consumers about the importance of proper disposal and recycling of light bulbs can reduce environmental impact and promote sustainable practices.

Customer Feedback and Co-Creation

• Product Improvement: Gathering feedback from customers helps manufacturers identify areas for improvement and develop products that better meet consumer needs.

• Co-Creation: Involving consumers in the product development process, such as through beta testing and focus groups, can lead to innovative features and higher satisfaction.

21. Global Market Dynamics

The light bulb manufacturing industry operates in a global market with diverse dynamics influencing demand, production, and innovation:

Regional Variations

• North America: The market is driven by high consumer demand for energy-efficient and smart lighting solutions. Stringent energy regulations and incentives for green buildings support the adoption of advanced lighting technologies.

• Europe: The European market emphasizes sustainability, with strong regulations on energy efficiency and hazardous substances. The EU’s commitment to reducing carbon emissions further boosts the demand for LED and smart lighting.

• Asia-Pacific: Rapid urbanization and industrialization in countries like China and India are driving growth. The region is also a major manufacturing hub, benefiting from lower production costs and technological advancements.

• Latin America and Africa: Emerging markets with growing economies and increasing electrification rates present opportunities for expansion. Affordability and energy efficiency are key factors driving consumer choices in these regions.

Trade Policies and Tariffs

• Impact on Costs: Trade policies and tariffs can significantly affect the cost structure of light bulb manufacturing, influencing sourcing decisions and pricing strategies.

• Supply Chain Resilience: Manufacturers must navigate global supply chains, ensuring resilience against disruptions such as trade conflicts, pandemics, and natural disasters.

Competitive Landscape

• Market Leaders: Established companies like Philips, GE, and Osram dominate the market with extensive product lines and strong brand recognition.

• Emerging Players: New entrants and startups are driving innovation, particularly in niche segments like smart lighting and specialty bulbs.

22. Sustainability and Corporate Social Responsibility (CSR)

Sustainability and CSR are increasingly important in the light bulb manufacturing industry, shaping company practices and consumer perceptions:

Eco-Friendly Manufacturing

• Green Manufacturing Practices: Companies are adopting green manufacturing practices, including reducing emissions, recycling waste, and using renewable energy sources in production facilities.

• Sustainable Materials: The use of sustainable and non-toxic materials in light bulb production is gaining traction, reducing environmental impact and promoting health and safety.

CSR Initiatives

• Community Engagement: Manufacturers are engaging with local communities through initiatives such as providing energy-efficient lighting to underserved areas, supporting education and awareness programs, and participating in local sustainability projects.

• Transparency and Reporting: Companies are increasingly transparent about their environmental impact and sustainability goals, publishing annual sustainability reports and setting ambitious targets for carbon neutrality and resource efficiency.

23. Technological Disruptions

Technological disruptions are reshaping the light bulb manufacturing landscape, offering new opportunities and challenges:

Artificial Intelligence and Machine Learning

• Predictive Maintenance: AI-driven predictive maintenance can identify potential issues in manufacturing equipment before they cause downtime, improving efficiency and reducing costs.

• Quality Control: Machine learning algorithms can enhance quality control processes by identifying defects and inconsistencies with high precision, ensuring consistent product quality.

Internet of Things (IoT)

• Connected Manufacturing: IoT enables connected manufacturing environments where machines and systems communicate in real time, optimizing production processes and reducing waste.

• Smart Lighting Solutions: IoT integration in lighting products allows for advanced features such as remote control, energy monitoring, and adaptive lighting based on user behavior and environmental conditions.

Blockchain

• Supply Chain Transparency: Blockchain technology can enhance supply chain transparency, ensuring traceability of materials and components, and verifying the authenticity of products.

• Consumer Trust: By providing verifiable data on the origin and production process of light bulbs, blockchain can build consumer trust and support ethical purchasing decisions.

An animation showing how to make a lightbulb with a screwdriver

24. Case Studies of Innovative Projects

Highlighting specific innovative projects can provide concrete examples of how the industry is evolving:

Philips Hue Ecosystem

• Comprehensive Smart Lighting: The Philips Hue ecosystem offers a wide range of smart lighting products, from bulbs to switches and sensors, all controllable through a single app or voice assistant.

• Interoperability: The system integrates seamlessly with major smart home platforms, including Amazon Alexa, Google Assistant, and Apple HomeKit, providing users with a flexible and cohesive lighting experience.

Osram’s Digital Farming Initiative

• Horticultural Lighting Solutions: Osram’s digital farming initiative leverages advanced LED lighting systems to optimize plant growth in controlled environments, improving crop yields and resource efficiency.

• Data-Driven Cultivation: The initiative uses data analytics to monitor and adjust lighting conditions in real-time, ensuring optimal growth conditions for different plant species.

25. Consumer-Centric Design

Focusing on consumer needs and preferences is crucial for the success of light bulb manufacturers:

User Experience (UX) Design

• Intuitive Interfaces: Designing user-friendly interfaces for smart lighting systems ensures that consumers can easily control and customize their lighting, enhancing satisfaction and engagement.

• Accessible Features: Including features that cater to diverse user groups, such as voice control and compatibility with assistive devices, makes lighting solutions more inclusive.

Product Customization

• Personalized Lighting: Offering customizable lighting options, such as adjustable color temperature and brightness, allows consumers to create personalized lighting environments that suit their preferences and needs.

• Aesthetic Appeal: Focusing on the aesthetic design of light bulbs, including shape, color, and materials, can attract consumers looking for both functionality and style.

26. Educational and Training Programs

The rapid evolution of the light bulb manufacturing industry necessitates continuous education and training to keep the workforce updated with the latest technologies and best practices:

Workforce Development

• Technical Training: Manufacturers are investing in technical training programs to ensure their workforce is proficient in the latest manufacturing techniques, quality control measures, and safety protocols.

• Certifications and Apprenticeships: Offering certifications and apprenticeships helps build a skilled workforce capable of meeting industry standards and adapting to new technologies.

Collaboration with Educational Institutions

• Industry-Academic Partnerships: Collaborating with universities and technical colleges helps align educational programs with industry needs, ensuring that graduates are ready to contribute effectively to the manufacturing sector.

• Internship Programs: Providing internships allows students to gain practical experience and exposure to real-world manufacturing environments, fostering a pipeline of talent for future employment.

Continuous Professional Development

• Workshops and Seminars: Regular workshops and seminars on topics like advanced materials, smart technology integration, and sustainability practices keep employees informed and motivated to innovate.

• E-Learning Platforms: Leveraging e-learning platforms allows employees to access training materials and courses at their convenience, promoting lifelong learning and professional growth.

27. Consumer Safety and Product Standards

Ensuring consumer safety and adhering to product standards are critical components of light bulb manufacturing:

Compliance with Regulations

• International Standards: Manufacturers must comply with international standards such as IEC (International Electrotechnical Commission) and ISO (International Organization for Standardization), which cover safety, performance, and environmental impact.

• Local Regulations: Adhering to local regulations and standards, such as those set by UL (Underwriters Laboratories) in the United States or CE (Conformité Européenne) marking in Europe, is essential for market entry and consumer trust.

Safety Features

• Overheat Protection: Implementing overheat protection mechanisms ensures that light bulbs operate safely even under prolonged use or adverse conditions.

• Non-Toxic Materials: Using non-toxic materials and reducing hazardous substances in light bulbs protect consumers and the environment.

Testing and Certification

• Third-Party Testing: Engaging third-party testing laboratories for product certification ensures impartiality and adherence to stringent safety standards.

• Consumer Feedback: Collecting and analyzing consumer feedback helps identify potential safety issues and improve product designs accordingly.

28. Marketing and Consumer Engagement

Effective marketing strategies and consumer engagement are vital for the success of light bulb manufacturers in a competitive market:

Digital Marketing

• SEO and Content Marketing: Utilizing SEO and content marketing strategies helps manufacturers attract and educate consumers online, driving traffic to their websites and increasing sales.

• Social Media Campaigns: Engaging consumers through social media platforms allows manufacturers to build brand awareness, showcase new products, and interact with customers directly.

Retail Partnerships

• Distribution Channels: Partnering with major retailers and online marketplaces ensures that products are widely available to consumers, enhancing market reach.

• Point-of-Sale Marketing: Effective point-of-sale marketing, including attractive packaging and in-store displays, can influence consumer purchase decisions and increase sales.

Customer Support and After-Sales Service

• Helplines and Chat Support: Providing accessible customer support through helplines and online chat services helps resolve consumer queries and issues promptly, improving satisfaction.

• Warranty and Return Policies: Offering comprehensive warranty and hassle-free return policies builds consumer trust and encourages repeat business.

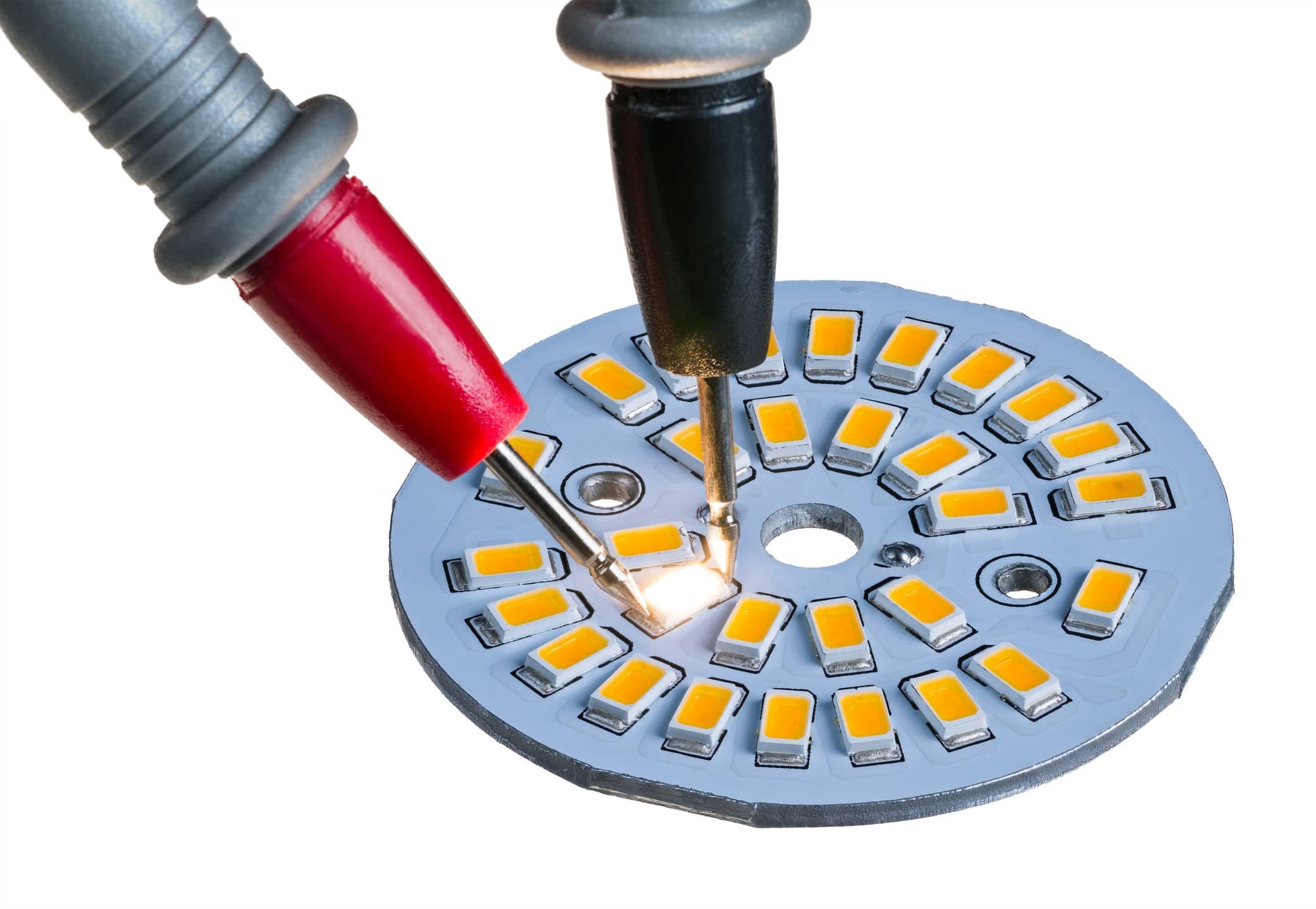

On a lightbulb circuit board, there are two screwdrivers pointing in the direction of a lit lightbulb chip

29. Future Innovations and Emerging Trends

The future of light bulb manufacturing is shaped by ongoing innovations and emerging trends that promise to revolutionize the industry:

Human-Centric Lighting (HCL)

• Biological Effects: Human-centric lighting focuses on the biological effects of light, such as improving mood, productivity, and sleep patterns by mimicking natural light cycles.

• Adaptive Lighting: Developing adaptive lighting systems that adjust based on time of day, occupancy, and user preferences can enhance well-being and energy efficiency.

Advanced Smart Lighting

• AI Integration: Integrating artificial intelligence into smart lighting systems can enable predictive lighting adjustments, energy optimization, and personalized lighting experiences.

• Interconnectivity: Enhanced interconnectivity with other smart home devices, such as thermostats, security systems, and entertainment systems, can create a more cohesive and intelligent living environment.

Sustainable Practices

• Circular Economy: Embracing the principles of the circular economy, such as designing for longevity, recyclability, and minimal waste, can reduce environmental impact and create sustainable business models.

• Energy Harvesting: Exploring energy harvesting technologies, such as solar or kinetic energy, can lead to innovative and self-sustaining lighting solutions.

Quizzes on the Light Bulb Manufacturing Process

Quiz 1:

Question: What is the primary raw material used in the manufacturing of incandescent light bulbs?

A. Plastic

B. Metal

C. Glass

D. Ceramic

Answer: C. Glass

Quiz 2:

Question: In LED light bulb manufacturing, what is the role of the semiconductor?

A. To conduct heat

B. To emit light

C. To provide structural support

D. To insulate the bulb

Answer: B. To emit light

Quiz 3:

Question: What gas is commonly used in the filling of incandescent light bulbs to prolong the filament's life?

A. Oxygen

B. Hydrogen

C. Argon

D. Carbon dioxide

Answer: C. Argon

Quiz 4:

Question: Which process involves the application of a phosphor coating inside the bulb in fluorescent light manufacturing?

A. Annealing

B. Phosphor coating

C. Tempering

D. Electroplating

Answer: B. Phosphor coating

Quiz 5:

Question: What is the main purpose of the filament in an incandescent light bulb?

A. To support the glass bulb

B. To emit light when heated

C. To conduct electricity

D. To cool the bulb

Answer: B. To emit light when heated

Quiz 6:

Question: How is the vacuum created inside an incandescent light bulb?

A. By heating the bulb

B. By blowing air into the bulb

C. By evacuating the air and sealing the bulb

D. By using chemical reactions

Answer: C. By evacuating the air and sealing the bulb

Quiz 7:

Question: What type of lighting technology uses a mixture of gases, including mercury vapor, to produce ultraviolet light, which then illuminates the phosphor coating?

A. Incandescent

B. LED

C. Fluorescent

D. Halogen

Answer: C. Fluorescent

Quiz 8:

Question: What is the significance of the base or socket in a light bulb?

A. It holds the filament in place

B. It provides the electrical connection

C. It controls the light output

D. It cools the bulb

Answer: B. It provides the electrical connection

Quiz 9:

Question: What advanced manufacturing process allows for the rapid prototyping of new light bulb designs?

A. Injection molding

B. Additive manufacturing (3D printing)

C. Die casting

D. Blow molding

Answer: B. Additive manufacturing (3D printing)

Quiz 10:

Question: Which quality control technique uses cameras and image processing software to inspect light bulbs for defects?

A. Manual inspection

B. Automated Optical Inspection (AOI)

C. Ultrasonic testing

D. X-ray inspection

Answer: B. Automated Optical Inspection (AOI)

Commonly Asked Questions with Answers on the Light Bulb Manufacturing Process

Question 1: What are the main steps involved in the manufacturing of incandescent light bulbs?

The manufacturing of incandescent light bulbs involves several key steps. First, the glass bulb is produced by blowing or molding molten glass into the desired shape. Next, the filament, typically made of tungsten, is drawn into a thin wire and coiled to increase its length and durability. The filament is then mounted on support wires and assembled with the bulb components, including the base and lead-in wires. The bulb is filled with an inert gas, such as argon or nitrogen, to prolong the filament's life, and then the bulb is sealed. Finally, the assembled bulb undergoes quality testing to ensure it meets safety and performance standards.

Question 2: How is the filament in an incandescent bulb made, and what material is commonly used?

The filament in an incandescent bulb is typically made from tungsten due to its high melting point and durability. Tungsten is first drawn into a thin wire and then coiled to increase its length and surface area, which enhances its ability to emit light when heated. The coiled tungsten wire is carefully shaped and mounted onto support wires, ensuring it is positioned correctly within the bulb to optimize light output and longevity.

Question 3: What distinguishes LED light bulbs from incandescent and fluorescent bulbs in terms of energy efficiency?

LED light bulbs are more energy-efficient than incandescent and fluorescent bulbs because they convert a higher percentage of electricity into light rather than heat. While incandescent bulbs produce a significant amount of heat and have a relatively short lifespan, LEDs generate very little heat and can last up to 25 times longer. Additionally, LEDs use semiconductor technology to emit light, which is inherently more efficient than the methods used in incandescent and fluorescent lighting.

Question 4: Why is a vacuum or inert gas used inside incandescent light bulbs?

A vacuum or inert gas, such as argon or nitrogen, is used inside incandescent light bulbs to prevent the tungsten filament from oxidizing and burning out quickly. In the presence of oxygen, the high temperatures reached by the filament would cause it to react and deteriorate rapidly. By removing the oxygen and replacing it with an inert gas or creating a vacuum, the filament can operate at high temperatures without undergoing chemical reactions that would shorten its lifespan.

Question 5: What is the role of phosphors in fluorescent light bulbs?

Phosphors play a crucial role in fluorescent light bulbs by converting ultraviolet (UV) light into visible light. When the electric current passes through the gas inside a fluorescent bulb, it produces UV light. This UV light then strikes the phosphor coating on the inside of the bulb, causing the phosphors to fluoresce and emit visible light. This process makes fluorescent bulbs more efficient at producing light compared to incandescent bulbs, which rely on heating a filament.

Question 6: How do manufacturers ensure the safety and quality of light bulbs?

Manufacturers ensure the safety and quality of light bulbs through rigorous quality control measures. These measures include automated optical inspection (AOI) to detect defects, electrical testing to ensure proper functioning, and environmental testing to verify performance under different conditions. Additionally, manufacturers must comply with international safety standards and regulations, such as those set by the International Electrotechnical Commission (IEC) and the Underwriters Laboratories (UL), to ensure their products are safe for consumer use.

Question 7: What environmental concerns are associated with the disposal of fluorescent light bulbs, and how can they be mitigated?

Fluorescent light bulbs contain mercury, a hazardous substance that poses environmental concerns if not disposed of properly. Improper disposal can lead to mercury contamination in landfills and the environment. To mitigate these concerns, it is essential to follow proper disposal and recycling programs. Many municipalities and retailers offer recycling services for fluorescent bulbs, ensuring they are handled and processed safely to prevent environmental contamination.

Question 8: What are the benefits of using lean manufacturing techniques in light bulb production?

Lean manufacturing techniques offer several benefits in light bulb production, including reduced waste, improved efficiency, and lower production costs. By streamlining processes, eliminating non-value-added activities, and focusing on continuous improvement, manufacturers can produce high-quality light bulbs more efficiently. Lean manufacturing also helps in minimizing inventory costs and reducing lead times, ultimately leading to better customer satisfaction and competitive pricing.

Question 9: How has automation impacted the light bulb manufacturing process?

Automation has significantly impacted the light bulb manufacturing process by increasing production speed, consistency, and precision. Automated systems and robotics are used for various tasks, such as assembling components, applying coatings, and conducting quality inspections. This reduces the likelihood of human error and ensures a higher level of uniformity in the finished products. Automation also enables manufacturers to scale up production quickly and efficiently, meeting market demand more effectively.

Question 10: What are some emerging trends in light bulb manufacturing?

Emerging trends in light bulb manufacturing include the integration of smart lighting technology, the use of sustainable materials, and the adoption of advanced manufacturing practices like additive manufacturing and digital twin technology. Smart lighting systems, which can be controlled remotely and offer features like dimming and color adjustment, are becoming increasingly popular. Additionally, manufacturers are focusing on sustainability by using recyclable materials and designing bulbs for easier recycling. Advanced manufacturing techniques, such as 3D printing, allow for rapid prototyping and customization, driving innovation in light bulb design and production.

10 Questions About Your Light Bulb Manufacturing Experience:

Have you ever worked in a light bulb manufacturing facility? If so, what was your specific role in the process?

What surprised you most about the number of steps involved in making a light bulb?

Did you ever witness a specific innovation or improvement in the light bulb manufacturing process during your time there? If so, can you elaborate?

What did you find most challenging about working in light bulb manufacturing?

In your experience, what quality control measures were most crucial for ensuring a functional light bulb?

Did you specialize in a particular type of light bulb (incandescent, LED, etc.)? Why or why not?

Looking back, are there any specific safety protocols that stand out in your memory?

What was the most rewarding aspect of working in light bulb manufacturing?

Have you ever had the opportunity to explain the light bulb manufacturing process to someone outside the industry? If so, what aspect surprised them the most?

Considering the rise of LED technology, how do you see the light bulb manufacturing process evolving in the future?

CONCLUSION

The light bulb manufacturing process is a sophisticated blend of material science, engineering, and precision manufacturing. From raw materials to the final product, each step is carefully controlled to produce reliable and efficient lighting solutions that meet modern standards for quality and energy efficiency. As technology advances, the industry continues to innovate, offering new and improved lighting options for consumers and businesses alike. The light bulb manufacturing industry is at the forefront of technological innovation and environmental sustainability. By embracing new technologies, improving energy efficiency, and prioritizing eco-friendly practices, manufacturers are poised to meet the evolving demands of consumers and regulatory bodies.

The future of light bulb manufacturing promises continued advancements that will enhance the way we illuminate our homes, workplaces, and public spaces. The evolution of light bulb manufacturing continues to impact various aspects of daily life and industry practices. By focusing on innovation, sustainability, and consumer preferences, manufacturers can stay ahead of the curve and contribute to a brighter, more efficient, and eco-friendly future. The ongoing advancements in technology and materials promise exciting developments in the world of lighting, making it an ever-evolving field with endless possibilities.

Harnessing the Power of LiFi Technology

LiFi (Light Fidelity) technology is revolutionizing the way we connect to the internet by using light waves instead of traditional radio frequencies like Wi-Fi. This cutting-edge technology transmits data through LED light bulbs that modulate their intensity at extremely high speeds, imperceptible to the human eye. By embedding a LiFi receiver in a device, such as a smartphone or laptop, users can connect to the internet when within range of a LiFi-enabled light source. This method not only offers incredibly fast data transfer rates but also enhances security, as light cannot penetrate walls, reducing the risk of unauthorized access. LiFi is especially useful in environments where radio frequency interference can be problematic, such as hospitals, airplanes, and industrial settings. To learn more about how LiFi technology can transform your connectivity experience, visit PairRecLiFi.

PRESIDENT OF PairRec

Chuck Johnson: Illuminating the Path of Light Bulb Manufacturing

Passion for Innovation

Chuck Johnson, the visionary leader behind PairRec, has dedicated his career to exploring and advancing the world of light bulb manufacturing. His deep-seated passion for lighting technology and manufacturing processes has driven him to become an industry expert, continuously pushing the boundaries of innovation in this field.

Expertise in Manufacturing Processes

With years of hands-on experience, Chuck possesses a profound understanding of the intricate processes involved in light bulb manufacturing. From the initial concept and design stages to the final production and quality control, Chuck's expertise ensures that every light bulb produced under his guidance meets the highest standards of efficiency, durability, and performance.

Commitment to Quality and Efficiency

Chuck's commitment to quality and efficiency is unwavering. He believes that the future of lighting lies in sustainable and energy-efficient solutions. Under his leadership, PairRec has adopted cutting-edge manufacturing techniques and stringent quality control measures to produce light bulbs that not only illuminate spaces but also contribute to environmental conservation.

Leader in Smart Lighting Technology

In addition to traditional lighting, Chuck is at the forefront of the smart lighting revolution. He has spearheaded the integration of advanced technologies into light bulb manufacturing, making smart bulbs that are not only energy-efficient but also equipped with features like remote control, color changing, and automation. Chuck's innovative approach ensures that PairRec remains a leader in the ever-evolving lighting industry.

Educator and Advocate

Beyond his role at PairRec, Chuck is a passionate educator and advocate for the lighting industry. He regularly shares his knowledge and insights through blogs, seminars, and industry conferences. His goal is to educate both consumers and industry professionals about the latest advancements in lighting technology and the importance of sustainable manufacturing practices.

Vision for the Future

Chuck's vision for the future of light bulb manufacturing is one where innovation, sustainability, and efficiency go hand in hand. He envisions a world where every light bulb produced not only meets the highest standards of quality but also contributes to a greener and more energy-efficient planet. Through PairRec, Chuck is committed to making this vision a reality, one light bulb at a time.

Stay tuned to the PairRec blog for Chuck Johnson's expert insights and updates on the latest trends and innovations in light bulb manufacturing. His dedication to excellence and passion for lighting technology continue to light the way for the industry.